Exhaust Systems

We have over 30 years of experience in delivering complete exhaust system assemblies to OEM manufacturers such as Valtra, Sandvik, and Proventia.

Water and Cooling Pipe Systems

We design and manufacture cooling systems according to the customer’s machine structure and flow requirements, using the steel grades specified by the customer.

Air and Oil Pipe Systems

Precisely measured and pressure-resistant solutions for hydraulic and lubrication systems. Designed and tested to operate reliably as part of the customer’s overall system.

Finse – Experts in Tube Processing

Industrial supply chains are increasingly built around locally operating manufacturers who can ensure the reliability, quality, and cost-efficiency of component deliveries.

Our production is designed to meet the stringent quality requirements of leading OEM-manufacturers. Every tube and component is produced within precisely defined tolerances.

This precision is enabled by CNC-controlled bending and forming technology, which ensures repeatable quality even in large production batches. All critical dimensions are verified with 3D measurements, and our quality system documents every stage for PPAP compliance.

We combine high production accuracy, documented quality management, and reliable delivery capability. This allows us to offer our customers a competitive and dependable solution—without compromising on quality or delivery reliability.

All Production Stages Under One Roof – Without Compromising on Quality

Bending and Forming

Processing thin-walled tubes requires a combination of precision, material expertise, and the right manufacturing methods. We have refined this expertise to a high level — we bend and form thin-walled steel tubes without deformation, wrinkling, or ovality, even with tight radii.

Welding and Joint Technology

All welding processes comply with standardized quality requirements (EN ISO 3834, EN ISO 9001), and critical joints are inspected through pressure and leak testing. In addition, welding parameters and filler materials are documented for each production batch, ensuring optimal results and repeatability.

Assembly and Testing

Our production covers everything from individual components to fully assembly-ready tube system assemblies, designed to integrate directly into the customer’s own production process.

Insulation and Finishing

Thermal insulation ensures that products meet the required heat management specifications in various applications. Effective insulation is just as important as mechanical performance for many of our customers. During the finishing stage, we inspect the visual quality of the product and add all necessary connection components.

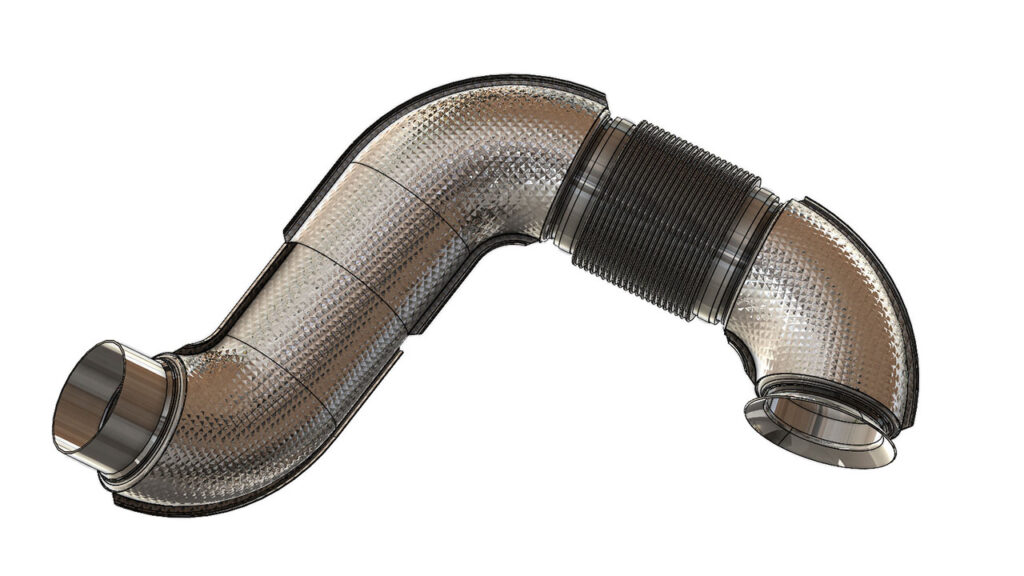

Exhaust Systems

We have more than 30 years of experience in manufacturing exhaust systems for demanding OEM customers such as Sandvik, Ponsse, AGCO, and John Deere.

Our long experience enables us to understand the requirements and characteristics of our customers’ production processes. This allows us to optimize our own manufacturing processes accordingly.

When we join the customer’s project and process already in the design phase, we can ensure cost-efficient and seamless production. We provide added value for our customers in areas such as:

- Designing routing and geometries (space utilization, bending radii, joint locations)

- Material selection and optimization of wall thickness (durability vs. weight)

- Thermal insulation using modern technologies (thermal conductivity, weight, appearance)

- Reviewing joint solutions and installability (compensators, sensor interfaces, brackets)

Early collaboration in the design phase enables cost savings in production and shortens lead times.

Designed for Direct Installation into Production

Our exhaust systems are always customer-specific, fully designed, and thoroughly tested assemblies that include all required components for the engine’s exhaust line: bent and formed tube elements, connectors, flexible elements, brackets, protective tubes, and sensor interfaces.

The system is delivered as a single, installation-ready assembly—dimensioned, documented, and tested for seamless integration into the customer’s production process.

Why finse?

Installation Readiness

Our deliveries fit directly into production without any adjustment work — saving time in every assembly.

Quality Assurance

Every component is tested, measured, and documented according to requirements — eliminating complaints and line interruptions.

Total Cost Savings

Fewer parts, faster installation, lighter structures — significantly lower lifecycle costs.

Fast Response

Our high-quality Finnish production and agile organization enable quick changes and additional deliveries without delays.

Partnership in Product Development

Water and Cooling Pipe Systems

Water and cooling system piping are precision components in engine and machinery applications, designed to manage engine-generated heat efficiently and reliably.

We design and manufacture cooling systems according to the customer’s machine structure and flow requirements, using the steel grades specified by the customer.

The result is a system that fits perfectly into the customer’s engine and cooling architecture, minimizing pressure losses and the risk of leaks.

To ensure the most cost-efficient and seamless production process, we recommend involving our team already in the design phase.

Tested and Ready for Installation

Our piping systems are always customer-specific, fully designed, and thoroughly tested assemblies. Together with the customer, we define the optimal bending radii, joint types, and materials. This ensures the required cooling performance without unnecessary weight or space requirements.

We deliver the piping as a single, installation-ready assembly — dimensioned, documented, and tested for integration into the customer’s production.

Every cooling pipe system is tested before delivery. Each unit undergoes pressure and leak testing as well as 3D scanning. This guarantees repeatability in serial production: every part and batch fits into place without adjustment — and meets OEM requirements from the very first installation.

Why finse?

Installation Readiness

Precisely measured and documented products fit directly into the assembly process.

Development Partnership

We participate already in the design phase to optimize flow, joints, and materials — accelerating approvals and improving final product performance.

Delivery Reliability

High-quality Finnish production and in-house testing ensure short lead times and consistent deliveries.

Longer Service Life

High-quality materials and precise joint technology ensure that the solution meets OEM standards and remains durable in use.

Air and Oil Pipe Systems

Air and oil piping systems are often invisible but critical components in many off-road machines and vehicles. They are responsible for lubrication, hydraulics, and compressed air management—where even a small error can lead to equipment failure or downtime.

Our strength lies in our ability to deliver these systems as customer-specific assemblies in which flow, durability, and installability are already optimized during the product development phase.

We master a wide range of pressure applications — from low-pressure air ducts to high-pressure hydraulic systems. This requires deep material expertise and precise process control, supported by our advanced bending processes, automated welding, and rigorous pressure and leak testing.

A Co-Designed Production Solution Improves the Final Outcome

The most production-efficient solution is achieved when we collaborate already in the early design phase. Together with the customer, we define the material grades, bending geometry, and joint requirements. This ensures that potential risks are identified during design, accelerates product approval for serial production, and guarantees that the final product functions seamlessly as part of the overall system.

Our bending processes and temperature-controlled welding enable thin-walled yet durable structures that reduce weight and improve flow efficiency — especially in mobile applications such as machinery and vehicles.

Our manufacturing processes ensure consistent, tight joints and strong wall structures that withstand the high pressures of hydraulic and lubrication systems.

All piping systems we manufacture undergo both pressure and leak testing, and we also perform 3D scanning. With 3D scanning, we can compare the manufactured pipes to the designed CAD model and verify that all tolerances match the agreed specifications.

Why finse?

Perfect Compatibility

Piping systems designed according to the customer’s hydraulic or lubrication system requirements — fully compatible.

Flow-Optimized Structure

Reduced pressure losses and a more efficient system = lower energy consumption.

Development Partner

Our engineers contribute to design and material selection — reducing risks and accelerating the prototype phase.

Reliable Production

100% tested and documented products ensure operational reliability and fast approval in OEM systems.

Delivery Reliability and Continuity

Our agile production enables quick response times and consistent deliveries without logistical delays.